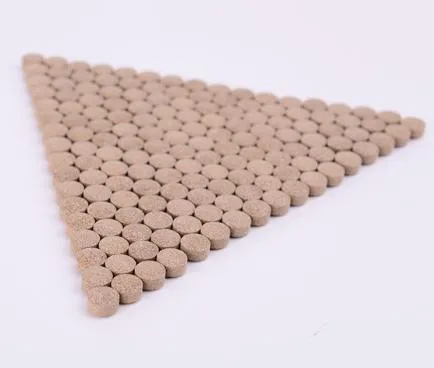

A coating tablet refers to a dosage form in which one or more layers of thin film are applied to the surface of a regular tablet through a special process. This technology is widely used in the pharmaceutical industry, which not only improves the stability and appearance of drugs, but also optimizes their release characteristics and enhances patient medication compliance. The main functions of coating tablets are reflected in the following aspects: protecting drug ingredients, controlling release speed, masking unpleasant odors, improving appearance, and facilitating identification.

Coating tablets can effectively protect drug ingredients from external environmental influence

Many drugs are sensitive to light, moisture, or oxygen and are prone to decomposition and failure during storage. For example, vitamin C is prone to oxidation in humid environments, while sugar coating or film coating can isolate moisture and extend the shelf life of drugs. In addition, enteric coated medicine tablets can protect drugs from damage in the gastric acid environment, ensuring their release in the alkaline environment of the small intestine, thereby improving efficacy and reducing irritation to the gastric mucosa.

Coating tablets can precisely control the release rate of drugs to meet different treatment needs

Slow release or controlled release coating in tablets adjusts the thickness and composition of the film to slow down drug release, maintain stable blood drug concentration, and reduce medication frequency. For example, some antihypertensive drugs use multi-layer coating tablets to achieve 24-hour stable release and avoid blood pressure fluctuations. This design not only improves the convenience of medication for patients, but also reduces the incidence of side effects.

Coating tablets can mask the unpleasant taste and odor of medication, improving the medication experience for patients, especially children

Many drugs have a bitter or pungent odor, such as antibiotics or traditional Chinese medicine tablets. Compressed coated tablets with sugar coating or mint flavor film can effectively neutralize the odor and improve patient acceptance. At the same time, colored coating tablets can also help distinguish between drugs of different specifications or uses, avoiding accidental ingestion. For example, cardiovascular drugs often use coating tablets in specific colors for elderly patients to identify.

The optimization of the appearance of the Coating Tablet is of great significance for brand building and market competition

Smooth and uniform continuous tablet coating can enhance the professionalism and credibility of drugs, while unique colors or logos can enhance brand recognition. In addition, Coating Tablets can reduce tablet wear and debris risks, ensuring integrity during transportation and storage.

In summary, Coating Tablets play multiple roles in pharmaceuticals, including protecting drug activity, regulating release, improving taste, and enhancing appearance. With the advancement of materials science and formulation technology, the coating tablet process will be further personalized to meet diverse clinical needs and provide patients with safer and more effective treatment options.

Coating Tablet FAQs

What is a Coating Tablet? What is its role in pharmaceuticals?

A coating tablet refers to a dosage form in which a special film is wrapped around the surface of a regular tablet. Its main functions include:

Covering up the bitterness or odor of drugs (such as antibiotics, traditional Chinese medicine extracts);

Protect drugs from gastric acid damage (such as enteric coated tablets);

Control drug release rate (such as sustained-release coating tablets);

Improve the appearance and stability of tablets (moisture-proof, light proof).

What are the common materials for coating tablets? How to choose?

Coating tablet materials can be divided into:

Coating Tablet (gradually phased out): sucrose+talc powder, low cost but complex process;

Film coating (mainstream): Hydroxypropyl methylcellulose (HPMC), polyvinyl alcohol (PVA), easy to operate;

Enteric coating: cellulose acetate phthalate (CAP), acrylic resin, resistant to stomach acid;

Extended release clothing: Ethyl cellulose (EC), Eudragit ®), Control drug release.

When choosing, drug properties (such as pH sensitivity), release requirements, and cost should be considered.

What are the key control points of the Coating Tablet process?

The core control points include:

Core quality: Moderate hardness (48kg), low brittleness (<1%), otherwise the Coating Tablet is prone to cracking;

Coating Tablet Liquid Formula: Solid content (usually 815%), plasticizer (such as PEG) ratio, affecting film-forming properties;

Process parameters: inlet air temperature (4060 ℃), spray gun pressure (1.52.5bar), pot speed (1020rpm), balancing drying efficiency and coating tablet uniformity;

Endpoint assessment: Weight gain of 25% (membrane coating), or thickness confirmed through online monitoring (near-infrared).

What quality issues may occur with the Coating Tablet? How to solve it?

Common problems and countermeasures:

Adhesive: Reduce the concentration of Coating Tablet solution and increase plasticizers or anti adhesives (such as talcum powder);

Cracking: Optimize the chip formula (such as adding microcrystalline cellulose) to reduce drying rate;

Color difference: Control the uniformity of the spray gun and use light blocking pigments (such as titanium dioxide);

Release non compliant (such as enteric coated tablets dissolving in the stomach): Check the thickness of the Coating Tablet and use a more acid resistant material (such as Eudragit) instead ® L100)。

What is the future development direction of Coating Tablet technology?

Innovation trends include:

Functional Coating Tablets: such as pH temperature dual responsive Coating Tablets (precision colon targeting);

Green Coating Tablet: Water based Coating Tablet replaces organic solvents or natural polymers (such as chitosan);

Continuous production: linked fluidized bed coating tablet equipment, achieving integration from tablet pressing to coating tablet;

3D Printing Coating Tablet: Customized Coating Tablet layer structure (such as gradient release).

Post time:Aug - 19 - 2025