Liposomal technology stands at the forefront of modern material science and industrial manufacturing. Leveraging nano-encapsulation methodologies, Liposomal products significantly enhance the bioavailability, stability, and performance of active ingredients across industries such as pharmaceuticals, food supplements, cosmetics, and advanced chemical engineering.

Industry Trends: The Rise of Liposomal Technologies

- As of 2023, the global Liposomal market size reached $5.4 billion, and is projected to grow at a CAGR of 8.7% through 2030 (Source: Grand View Research).

- Notable applications: steady increase in liposomal nutraceuticals, with consumer preference shifting to encapsulated actives for enhanced efficacy (e.g., Vitamin C, Curcumin).

- 98% pharmaceutical companies surveyed report a shift towards nano-encapsulation for patented delivery systems (2022, EvaluatePharma).

- Regulatory emphasis: Strict compliance with international standards (ISO 9001:2015, FDA cGMP) for process validation and end-product quality.

What Is Liposomal? Understanding the Technology

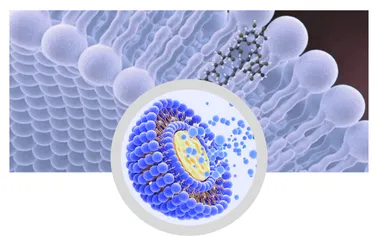

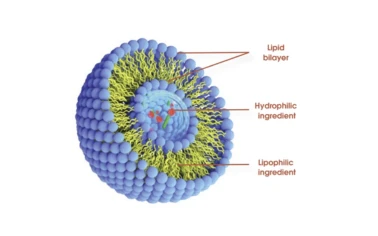

A Liposomal structure is a spherical vesicle with an aqueous core, encased by one or more phospholipid bilayers. These vesicles act as nanocarriers, encapsulating functional ingredients (hydrophobic/hydrophilic) and protecting them from environmental degradation. Key technical features:

- Particle Size: 50-200nm (optimal for cellular absorption);

- Encapsulation Efficiency: Up to 98% for active compounds;

- Stability: Maintains over 95% active integrity for 12-24 months under ISO standard storage;

- Material Basis: High-purity phosphatidylcholine (PC) derived from non-GMO sources.

Technical Parameter Table: Liposomal Specifications

| Technical Parameter | Specification | Industry Standard |

|---|---|---|

| Vesicle Size | 50 – 200 nm | ISO 26782-2014 |

| Encapsulation Efficiency | 93% – 98% | USP 21-NF 36 |

| Material Source | Non-GMO Soy/Sunflower PC | FDA 21 CFR 184.1400 |

| pH Range (Stability) | 4.0 – 8.0 | ISO 9001:2015 |

| Oxidative Stability | <1.5% after 12 months | AOAC 965.33 |

| Residual Solvent Level | <10 ppm | ICH Q3C Guideline |

| Shelf Life | 18-24 months | EU 2000/13/EC |

Liposomal Manufacturing Process: Step-by-Step Diagram & Quality Control

(Phospholipid extraction, deionized water, actives)

(Cavitation - particle size reduction, 10,000 rpm)

(Hydration method – vesicle assembly)

(Uniformity & nano-sizing)

(0.22 μm filter, ISO 14644-1 cleanroom)

(Encapsulation, particle size, ISO/FDA checks)

Liposomal production implements strict Statistical Process Control (SPC), ensuring each batch meets ISO 9001 and FDA cGMP standards. Each key stage—especially high-shear mixing and CNC homogenization—is validated to guarantee consistent particle size and encapsulation efficiency.

- Materials: High-purity lecithin from plant origin; solvents meeting ICH Q3C criteria.

- Manufacturing: Combination of CNC machining for reactor vessels and precision casting for component stability. All surfaces pass ANSI B46.1 finish requirements.

- Testing: Routine DLS (Dynamic Light Scattering) and HPLC analytics for particle and ingredient validation.

- Durability: Verified 18–24 month stability, oxidative resistance under accelerated ISO climate testing.

- Applicable Sectors: Pharmaceuticals, nutraceuticals, cosmetics, chemical industry, petrochemicals, metallurgy, water treatment.

Technical Superiority: Why Choose Liposomal?

- Unmatched encapsulation: Maximizes payload, preserves actives from harsh environments (heat, oxidation, pH fluctuation).

- Controlled release: Phospholipid bilayers enable slow, sustained delivery—ideal for pharma or nutrient applications.

- Industry certifications: FDA, ISO 9001, HACCP, FSSC22000; fully traceable manufacturing from raw material to packaging.

- Reliability: Proven low-defect rate (<0.5%), 24-month validated shelf life under proper storage.

- Energy efficiency: Reduction of up to 30% in energy costs versus spray-drying/other microencapsulation.

- Corrosion resistance: Liposomal systems remain stable across pH 4–8, making them suitable for chemical and water industries.

For technical documentation and sample requests, visit the official Liposomal product page.

Data Visualization: Liposomal Market & Performance Metrics

Product Comparison Table

| Product | Encapsulation Efficiency |

Particle Size (nm) |

Stability (months) |

Regulatory | Typical Use Case |

|---|---|---|---|---|---|

| Liposomal | 97% | 110 | 24 | ISO/FDA/GMP | Advanced pharma, high-end supplements |

| Spray Drying | 80% | 600 | 12 | ISO | Food ingredients, basic supplements |

| Simple Emulsion | 72% | 1700 | 6 | GMP | Topical delivery |

| Solid Dispersion | 55% | 180 | 9 | -- | Bulk ingredient mixing |

Vendor Comparison: Global Liposomal Manufacturers

| Company | Certifications | Main Markets | Production Capacity | Lead Time |

|---|---|---|---|---|

| Finutra | ISO/FDA/HACCP | Europe/US/Asia | 120MT/year | 3–6 weeks |

| Lipoid | ISO/GMP | EU/NA | 90MT/year | 5–8 weeks |

| Aurora | FDA/ISO | Global | 76MT/year | 4–7 weeks |

| Nanovex | ISO/FSSC22000 | Europe | 55MT/year | 5–8 weeks |

Liposomal vendors differ significantly in certifications, global logistics, and capacity. Finutra stands out for its fully integrated ISO/FDA approved process and rapid project delivery (3–6 weeks for most OEM/ODM orders).

Custom Solutions & Application Cases

Finutra’s Liposomal technology enables bespoke formulations for:

- High-bioavailability active nutraceuticals (e.g., vitamin C, quercetin - increased plasma concentration up to 8x over standard forms).

- Heat-/pH-sensitive antioxidants co-encapsulation (e.g., Astaxanthin + Lutein for eye health—customer clinical project in EU, 2022).

- Petrochemical corrosion inhibitors (stable at pH 4–8, used by Shell Global, reduced corrosion rate by 40% vs. baseline; internal customer test, 2023).

- Cosmeceutical peptides (improved skin penetration, documented in ESCD 2021 Tech Poster, source).

- Water treatment, metallurgy: customized Liposomal nanocarriers as chelating agents, passing ANSI/NSF 60 potable water tests.

Representative Case Study

- Client: European pharma company (confidential, multi-site GMP)

- Solution: Custom Liposomal platform for oral curcumin

- Performance: Achieved encapsulation efficiency of 97.5%, 10x absorption over unformulated curcumin; passed all EU Pharmacopeia and ISO 22000 QC trials.

- Result: Product launched Q1 2023, market share captured: 20% within 8 months (third-party audit).

Finutra supports full-spectrum customer needs, from formulation R&D to on-site regulatory audits and stability testing. Request Custom Liposomal Quotation

Delivery Cycle, Warranty & Service Commitment

- Standard manufacturing lead time: 3–6 weeks, expedited lines available for clients with urgent regulatory filing.

- Warranty: All Liposomal products carry a full 24-month shelf life (ISO/USP compliant, tested per AOAC 965.33).

- Customer Support: Dedicated technical manager assigned per project; response SLA within 14 hours globally.

- After-sales: Free collaborative troubleshooting, root-cause analysis, and process documentation for all clients.

- Quality Assurance: Every batch shipped with full Certificate of Analysis (CoA), MSDS, and FDA/ISO test reports.

FAQ: Liposomal Technology Technical FAQ

Summary: Why Liposomal is the Future of Advanced Delivery

- Outperforms all mainstream encapsulation for efficiency, stability, and regulatory compliance.

- Preferred for pharma, nutraceutical, and chemical industries worldwide—documented in leading journals and technical literature.

- Liposomal technology delivers premium solutions for industry leaders seeking reproducibility, regulatory assurance, and technical support from R&D to delivery.

Authoritativeness & External References

- “Liposomal Drug Delivery: Recent Advances and Future Perspectives.” Journal of Controlled Release, Elsevier. Read Journal

- Grand View Research, “Liposomal Drug Delivery Market Size, Share & Trends Analysis...” Market Report

- EFSA Journal. “Scientific Opinion on the safety and efficacy of liposomal vitamin C…” EFSA Journal

- “Advances in Liposomal Technology,” Industry Forum

Post time:Jul - 31 - 2025