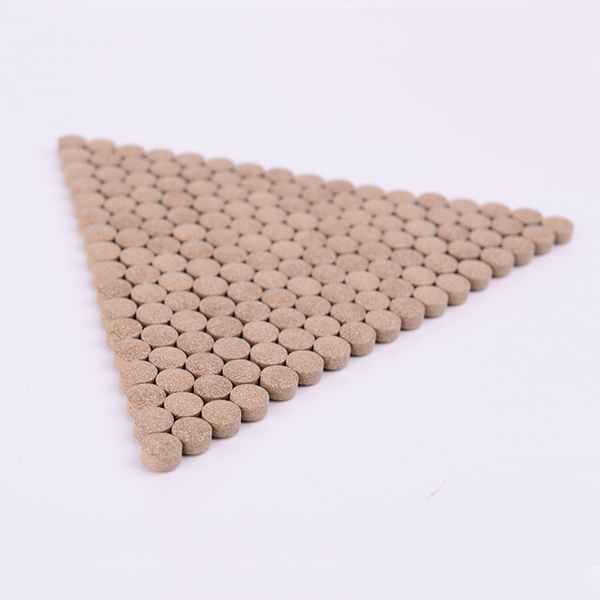

Unlocking Pharmaceutical and Nutraceutical Excellence with Coating Tablet OEM/ODM Premix Service

In the dynamic and highly regulated sectors of pharmaceuticals and nutraceuticals, the precise formulation and delivery of active ingredients are paramount. This is where Coating Tablet OEM/ODM Premix Service plays a pivotal role. It represents a sophisticated solution for companies seeking to outsource the complex processes of tablet manufacturing, from initial concept to final coated product. This service encompasses the entire value chain, leveraging specialized expertise and state-of-the-art facilities to ensure product efficacy, stability, and consumer appeal. Our focus on quality, innovation, and adherence to global regulatory standards positions us as a critical partner for brands aiming for market leadership.

The demand for bespoke solutions in tablet manufacturing is growing, driven by consumer preferences for tailored dosages, improved palatability, and extended shelf life. Our comprehensive approach to Coating Tablet OEM/ODM Premix Service addresses these needs by integrating advanced material science with precision engineering. This allows for the development of tablets with specific release profiles, enhanced stability against environmental factors, and an appealing finish that encourages patient compliance. We navigate the intricacies of active pharmaceutical ingredients (APIs) and nutritional compounds, ensuring their integrity and optimal delivery through meticulously designed coating systems.

The Advanced Manufacturing Process of Coating Tablets

Our Coating Tablet OEM/ODM Premix Service involves a meticulous, multi-stage manufacturing process designed to achieve superior product quality and performance. Each step is rigorously controlled to meet global standards such as ISO 9001 and cGMP (current Good Manufacturing Practices), ensuring consistency and reliability. The journey begins with the careful selection of raw materials, including active ingredients, excipients, and coating components, all of which undergo stringent quality checks upon arrival.

- Material Sourcing & Quality Control: Selection of pharmaceutical-grade APIs, excipients (binders, disintegrants, diluents), and coating polymers. All materials are verified against specifications using analytical techniques like HPLC, FTIR, and GC-MS.

- Premixing & Blending: Precise weighing and homogeneous mixing of dry ingredients in controlled environments to create a uniform blend. This critical step ensures content uniformity throughout the tablet batch.

- Granulation (Wet or Dry): For optimal flow and compressibility, raw materials may undergo granulation. Wet granulation involves adding a liquid binder, followed by drying and milling. Dry granulation uses compaction without liquid, suitable for moisture-sensitive ingredients.

- Tablet Compression: The blended or granulated material is fed into high-speed tablet presses, which form individual tablets under immense pressure. Parameters like tablet hardness, thickness, and weight are continuously monitored.

- Coating Application: Tablets are transferred to specialized coating pans where a fine spray of coating solution is applied. This process requires precise control over spray rate, air temperature, and pan speed to achieve a uniform and defect-free film. Various coating types are applied, including film coating for protection and appearance, enteric coating for targeted release in the intestines, and sugar coating for palatability.

- Drying & Curing: Post-coating, tablets are dried to remove residual solvents and cure the coating, ensuring its durability and integrity.

- Quality Assurance & Packaging: In-process checks for friability, dissolution, disintegration, and visual appearance are performed. Final products undergo comprehensive quality control before being packaged in materials designed to preserve stability and extend shelf life. This rigorous process ensures each Coating Tablet OEM/ODM Premix Service unit meets stringent quality benchmarks.

The materials used in our Coating Tablet OEM/ODM Premix Service vary depending on the product's specific requirements. Common coating materials include hypromellose (HPMC) for general film coating, cellulose acetate phthalate (CAP) or Eudragit for enteric release, and various sugars for traditional sugar coating. Each material is selected for its functional properties, biocompatibility, and regulatory compliance, ensuring the final product meets all safety and performance criteria.

Technical Parameters and Customization Capabilities

Our expertise in Coating Tablet OEM/ODM Premix Service allows for extensive customization to meet unique product specifications. Key technical parameters we manage include tablet size and shape (from 5mm to 20mm, various shapes), hardness (typically 5-20 Strong-Cobb units), friability (less than 1%), and precise dissolution profiles (immediate release, sustained release, enteric release). These parameters are critical for achieving desired therapeutic outcomes and ensuring consumer satisfaction.

| Parameter | Description | Typical Range/Specification | Benefits/Impact |

|---|---|---|---|

| Tablet Size & Shape | Customizable dimensions and geometry (e.g., round, oval, capsule, specialty) | 5mm to 22mm diameter; varied thickness | Improved swallowability, brand differentiation, dosage control. |

| Tablet Hardness | Resistance to crushing, measured in Newtons (N) or kp | 50 N - 150 N (approx. 5-15 kp) | Ensures tablet integrity during handling, packaging, and shipping. |

| Friability | Tablet's tendency to crumble, measured as percentage weight loss | Typically < 1% (USP/EP standard) | Indicates resistance to abrasion, crucial for robust products. |

| Disintegration Time | Time required for a tablet to break up into smaller particles in a specified medium | Varies by formulation; often < 30 minutes (USP) | Crucial for rapid drug release and absorption. |

| Dissolution Rate | Rate at which the active ingredient dissolves from the tablet into a solution | Custom profiles (e.g., Q value at specific time points) | Determines bioavailability and therapeutic effect, especially for sustained/enteric release. |

| Coating Thickness Uniformity | Consistency of the coating layer across all tablets | Typically ±10% variation | Ensures consistent protection, appearance, and release properties. |

Our Coating Tablet OEM/ODM Premix Service is highly adaptable, catering to various dosage strengths and complex formulations. Whether it's a multi-layer tablet or a specialized coating for moisture sensitivity, our R&D team can develop and validate the optimal solution. We leverage advanced analytical techniques and stability chambers to predict shelf life and ensure product integrity under diverse environmental conditions.

Applications and Strategic Advantages

The versatility of our Coating Tablet OEM/ODM Premix Service makes it invaluable across several industries. Primarily, we serve the pharmaceutical, nutraceutical, dietary supplement, and veterinary medicine sectors. In pharmaceuticals, it's crucial for taste masking bitter APIs, protecting acid-labile drugs with enteric coatings, and achieving sustained release for chronic conditions. For nutraceuticals and dietary supplements, coating enhances product stability, extends shelf life, improves visual appeal, and masks undesirable flavors or odors, leading to higher consumer acceptance.

Our technical advantages stem from decades of specialized experience and continuous investment in cutting-edge technology. We pride ourselves on:

- Enhanced Bioavailability: Through precise dissolution profiles and specialized coatings, we optimize the absorption of active ingredients.

- Improved Stability & Shelf-Life: Coatings provide a barrier against moisture, light, and oxidation, significantly extending product viability.

- Taste & Odor Masking: Essential for palatable supplements and medications, improving patient compliance.

- Targeted Delivery: Enteric coatings ensure active compounds are released only in the intestines, protecting sensitive ingredients from stomach acid and reducing gastric irritation.

- Brand Differentiation: Custom colors, shapes, and finishes elevate brand identity and consumer recognition.

A key benefit of utilizing our Coating Tablet OEM/ODM Premix Service is the significant cost-efficiency and accelerated time-to-market it offers. Companies avoid the substantial capital investment in specialized machinery, facility setup, and highly skilled personnel, redirecting resources to core competencies like marketing and research. This strategic partnership allows brands to scale operations quickly and respond to market demands with agility, ensuring a competitive edge in rapidly evolving markets.

Commitment to Quality and Trustworthiness

Our unwavering commitment to quality and compliance is the cornerstone of our Coating Tablet OEM/ODM Premix Service. We operate under stringent quality management systems, holding certifications such as ISO 9001, and adhering strictly to cGMP guidelines set forth by regulatory bodies like the FDA and EMA. All manufacturing processes are documented and traceable, ensuring full transparency and accountability from raw material intake to finished product release.

Quality Assurance and Certifications: We perform extensive in-process and finished product testing, including dissolution tests, active ingredient assays, uniformity of dosage, microbial limits, and stability studies. Our facilities are regularly audited by independent third parties and clients, consistently demonstrating our adherence to the highest quality benchmarks. This robust framework ensures that every batch produced through our Coating Tablet OEM/ODM Premix Service is safe, effective, and meets all regulatory requirements.

Delivery and Support: We understand the importance of timely delivery in a competitive market. Our streamlined production processes and robust supply chain management enable efficient lead times, typically ranging from 8-12 weeks for new formulations after final specification approval, and shorter for reorders. Our dedicated client support team provides continuous communication, from project initiation through to post-delivery, ensuring a seamless experience. We offer comprehensive technical support, formulation guidance, and regulatory assistance to help clients navigate the complex landscape of product development and market entry.

Frequently Asked Questions (FAQ)

Q: What is the minimum order quantity (MOQ) for your Coating Tablet OEM/ODM Premix Service?

A: Our MOQ varies depending on the complexity of the formulation and the specific coating requirements. Typically, it starts from 500,000 tablets for standard formulations. We encourage prospective clients to discuss their specific needs with our sales team for a precise quotation and feasibility assessment.

Q: Can you help with custom formulation development for my product?

A: Absolutely. Our Coating Tablet OEM/ODM Premix Service includes comprehensive R&D support. Our team of formulation scientists can assist with developing unique formulations, optimizing existing ones, and selecting appropriate coating systems to achieve desired product attributes such as specific release profiles, enhanced stability, or improved taste masking.

Q: What quality certifications do your manufacturing facilities hold?

A: Our facilities adhere to the highest international quality standards. We are ISO 9001 certified and operate under strict cGMP guidelines. We also comply with relevant regulatory requirements from bodies such as the FDA (for dietary supplements and pharmaceuticals in the US market) and similar agencies worldwide, ensuring our Coating Tablet OEM/ODM Premix Service meets global expectations.

Q: What is your typical lead time for a new project?

A: For new Coating Tablet OEM/ODM Premix Service projects, the lead time typically ranges from 8 to 12 weeks from the final approval of formulation and packaging specifications. This period includes raw material sourcing, production scheduling, manufacturing, quality control, and packaging. Reorders for existing products generally have shorter lead times.

References

- United States Pharmacopeia (USP). "General Chapters: The Dissolution Procedure: Development and Validation." Current Edition.

- European Pharmacopoeia (Ph. Eur.). "2.9.3. Dissolution Test for Solid Dosage Forms." Current Edition.

- Food and Drug Administration (FDA). "Guidance for Industry: Tablet Scoring - Q & A." U.S. Department of Health and Human Services, 2013.

- International Organization for Standardization (ISO). "ISO 9001:2015 - Quality management systems - Requirements."

- Rowe, R. C., Sheskey, P. J., & Quinn, M. E. (Eds.). (2009). Handbook of Pharmaceutical Excipients. Pharmaceutical Press.

Post time:Aug - 11 - 2025