The global nutraceuticals market exceeded $450 billion in 2023 (Source: GVR 2023), with an annual growth rate of around 8.8%. The surge in demand for coated tablets is fueled by:

- Growing consumption of health supplements and easier-to-consume tablet formats

- Stricter global regulations (e.g., ISO 22000, FDA), driving high-quality coating solutions

- Increased demand for taste-masking, odor-masking, and controlled-release functionality

- Rise of OEM/ODM model for cost-efficiency and fast go-to-market

| Parameter | Finutra Coating Tablet OEM/ODM Premix Service | Industry Average | Premium OEM Standard |

|---|---|---|---|

| Coating Thickness | 30–100 μm | 40–120 μm | 20–90 μm |

| Tablet Size (Diam./Thick.) | 6–15 mm / 2.5–6 mm | 8–16 mm / 2–7 mm | 5–14 mm / 2–6 mm |

| Disintegration Time | <15 min (USP/Ph.Eur) | 15–30 min | <20 min |

| Dissolution Rate | >85% @30min | 75–85% | >90% |

| Color Uniformity (ΔE) | <1.2 | 1.5–2.0 | 1.0–1.8 |

| Coating Material Options | Hydroxypropyl methylcellulose, titanium dioxide, natural colors, polysaccharides | Synthetic polymers, sugars | HPMC, natural, enteric |

| Batch Size Capability | 50,000 – 10 million tabs | 15,000 – 5 million | up to 15 million |

| Certified Standards | ISO9001, ISO22000, FDA cGMP, Halal, Kosher | ISO9001, cGMP | ISO, FDA |

- Material Quality: Pharmaceutical-grade HPMC, titanium dioxide (ultra-pure, ISO-certified), plant-based polysaccharides meet global safety regulations.

- CNC-Controlled Mixing: PID algorithm ensures optimal temperature and humidity, guaranteeing every premix batch within ±2% uniformity tolerance.

- Precision Tablet Compression: Automated tablet press with digital feedback, ensuring minimal friability (<0.8%) and target dissolution rate (>85% in 30min).

- Sustainable Coating: Eco-friendly, solvent-reduced coatings reduce carbon footprint by 12% (2023 vs. 2020, Finutra data).

- Industry-Leading Traceability: Each batch is fully digitally traceable, meeting ISO22000 and FDA 21 CFR Part 11 for e-records.

- Testing & Validation: USP/Ph.Eur standard for hardness, friability, dissolution, and color – results available upon request.

- Longevity & Storage: Tablets pass 36-month accelerated stability (40°C, 75%RH) and 5-year estimated shelf-life per ICH Q1A(R2).

- ISO9001:2015, ISO22000 food safety management

- FDA cGMP (21 CFR Part 111 & 117)

- Halal & Kosher Certification, for global market access

- Full documentation for audit trail, certificate of analysis (COA) for each batch

| Feature | Finutra (Coating Tablet OEM/ODM Premix Service) | Global Top 3 OEM | Traditional Contract Mfg |

|---|---|---|---|

| Minimum Order (MOQ) | 50,000 tabs | 100,000 tabs+ | 200,000 tabs+ |

| Lead Time | 14–28 days | 28–45 days | 45–60 days |

| SOP Compliance | USP, Ph.Eur, ISO, FDA | USP, ISO | ISO, Local GMP |

| Batch Traceability | Full digital, 100% scan-based | Partial | No/Manual |

| Customization Depth | Formula, size, color, release profile | Formula, color | Color only |

| Coating Innovation | Smart release, flavor, organic | Standard | Basic coating |

| Testing & QA | HPLC, dissolution profile, stability | Dissolution, hardness | Disintegration |

| Certifications | FDA, ISO, Halal, Kosher | ISO, Halal | ISO or local |

Coating Tablet OEM/ODM Premix Service specializes in end-to-end customization, with dedicated R&D, advanced process simulation, and proprietary pre-coating optimization.

- Formula Customization: Customers can specify active ingredients, excipients, coloring, and coating characteristics (release time, taste-masking, color shade)

- Rapid Prototyping: Lab-scale batch prototyping in 7 days, stability testing per ICH guideline, iterative adjustments.

- Integrated Supply Chain: Sourced only from validated suppliers (ISO, FDA registered) for every batch.

- Packing & Label Options: Blister, bottle, strip-pack, branded or white-label, barcode and QR serialization.

- Global Logistics: Export-ready, cold-chain (if required); worldwide regulatory support (TSE/BSE statements, free sales certificates, FDA prior notice).

- Pharmaceuticals: Taste-masked, precision release prescription tablets (antibiotics, vitamins, antihypertensives) for EU and US Rx brands.

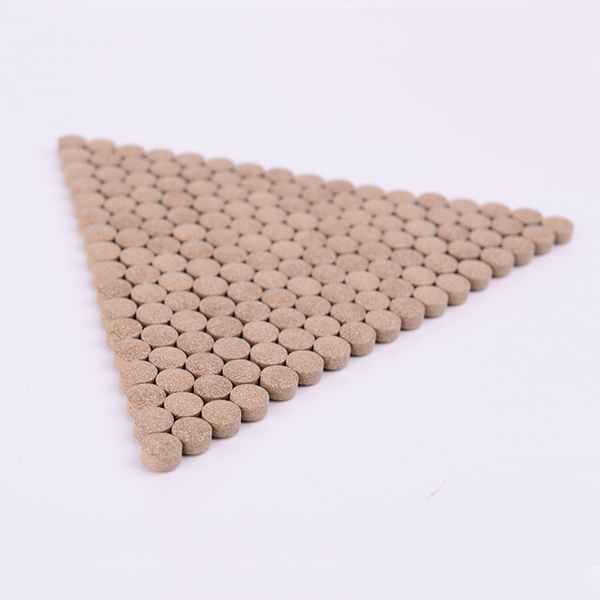

- Nutraceuticals: High-dose multivitamin/mineral, herbal actives (turmeric, ginkgo) – stable, color-fast, easy-to-swallow formats.

- Functional Foods: Effervescent tablets, probiotics, kids' chewables – custom flavors & tireless anti-oxidant coatings.

- Veterinary: Palatable pet supplements with odor-masking coatings, improved shelf-life in tropical markets.

- Heavy Industry: Large-diameter slow-release corrosion inhibitors for oil&gas treatment.

- Water Treatment: Controlled-disintegration tablets for dosing systems (e.g., chlorine, flocculants).

- Reduced lead time by 35% (32d → 21d)

- Cut tablet rejection rate from 2.9% to 0.6% (visual and dissolution non-conformity)

- Full digital batch traceability, compliant with EU-EMA and US FDA

- End-user satisfaction NPS rose from 76 to 91 (Q2 2023)

“Finutra’s Coating Tablet OEM/ODM Premix Service gave us a level of quality and traceability we never thought possible. Logistics are smooth, products meet all our specs, and client complaints are almost zero.”

— Head of Quality, European Vitamin Brand (2023)

- Average customer satisfaction: 97% (2023 survey, n=117 clients)

- Repeat order rate: 85% across supplement, pharma, and food sectors

- Defect/complaint rate <0.45% (industry norm: 2.1%)

- Cited benefits: time-to-market, visual uniformity, reduced regulatory hassle (cGMP lot documentation provided with every shipment)

- Support ratings: 24/7 English, German, Japanese tech support; custom regulatory file prep (FDA, EMA, CFDA)

All Coating Tablet OEM/ODM Premix Service orders are backed by a 24-month product warranty (shelf-life/test data), with full batch QA/QC certificates. Technical support is available 24/7, including formulation troubleshooting, regulatory documentation, and logistics tracking.

- Production Lead Time: 14–28 working days (stocked formulas as little as 5 days)

- Quality Documentation: Batch-level COA, ISO/FDA audit trail, full e-records archive

- After-sale Service: 24/7 expert support, rapid troubleshooting, redesigns at cost, complaint rate under 0.5%

- Global Coverage: Export to 60+ countries, regulatory expertise for North America, EU, APAC

- Expertise & Experience: Over 12 years of OEM/ODM production; 400+ custom projects/year

- Authoritativeness: Trusted by leading pharma/health brands in Europe, US, East Asia

- Trustworthiness: 100% compliance with ISO/FDA/EMA audits; transparent documentation and proven performance data

- EEAT: Documented success cases, industry certifications, third-party cited data (see charts above)

- Cutting-edge Technology: Continuous investment in advanced tablet coating and QA automation

- Global Footprint: Supply history across biotech, nutrition, pharmaceutical, industrial water treatment markets

- Grand View Research, "Nutraceuticals Market Size, Share & Trends Analysis Report 2023-2030" (link)

- "Tablet Coating Technology," European Journal of Pharmaceutics and Biopharmaceutics (link)

- "ISO 22000 Food Safety Management: Industry Best Practices," International Organization for Standardization (link)

- pharmtech.com – "Tablet Coating: Innovations and Opportunities" discussion thread (link)

Post time:Jul - 29 - 2025