Unlocking Growth with Advanced Chewable Tablet OEM & ODM Services

In the rapidly evolving health and wellness industry, the demand for convenient and consumer-friendly dosage forms is surging. Among these, chewable tablets have emerged as a significant segment, offering an appealing alternative to traditional pills. They are particularly favored for their ease of consumption, improved patient compliance, and ability to mask unpleasant tastes, making them ideal for a wide range of demographics, including pediatric, geriatric, and individuals with dysphagia. For businesses looking to penetrate or expand within this dynamic market, leveraging specialized Chewable Tablet OEM&ODM Service providers offers a strategic advantage. This service encompasses everything from initial concept and formulation development to manufacturing, quality assurance, and packaging, providing a comprehensive, end-to-end solution for bringing novel chewable products to market efficiently and effectively.

The journey from a mere idea to a market-ready chewable tablet is complex, requiring deep expertise in pharmaceutical science, advanced manufacturing capabilities, and stringent quality control. Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) models allow brands to outsource this intricate process to specialists, ensuring high-quality products without the massive upfront investment in R&D and manufacturing infrastructure. This strategic partnership enables companies to focus on their core competencies, such as marketing and distribution, while benefiting from the manufacturer's technical prowess and regulatory compliance. The flexibility offered by these services extends to ingredient sourcing, flavor profiles, tablet shapes, and packaging designs, ensuring the final product aligns perfectly with brand identity and target consumer needs. This article delves into the critical aspects of this service, highlighting its profound impact on market trends, technical execution, and strategic business growth.

Industry Trends and Market Dynamics for Chewable Tablets

The global market for chewable tablets is experiencing robust growth, driven by several key trends. Consumers are increasingly seeking convenient and palatable alternatives to traditional capsules and tablets, particularly in the dietary supplement and nutraceutical sectors. This shift is fueled by a heightened awareness of preventive healthcare and a growing preference for functional foods and supplements that offer specific health benefits. The pediatric and geriatric populations, in particular, benefit significantly from chewable forms due to swallowing difficulties (dysphagia), leading to enhanced medication adherence and nutritional supplementation. Furthermore, the rising demand for immunity boosters, vitamin supplements, and specialized nutritional products in an easy-to-consume format continues to propel market expansion.

Emerging trends also include the integration of novel active ingredients, such as probiotics, prebiotics, adaptogens, and specialized botanical extracts, into chewable formats. This requires sophisticated formulation techniques to maintain ingredient stability and efficacy while ensuring desirable taste and texture. Technological advancements in flavor masking and texture modification are critical in overcoming the challenges posed by these complex ingredients. The market is also seeing a surge in personalized nutrition, where consumers seek products tailored to their specific dietary needs and preferences, driving demand for flexible and customizable OEM/ODM solutions. Regulatory landscapes, such as those set by the FDA and EMA for pharmaceuticals, and various food safety standards for nutraceuticals, constantly evolve, requiring manufacturers to maintain rigorous compliance and quality systems like cGMP (current Good Manufacturing Practices) and ISO certifications.

Figure 1: State-of-the-art manufacturing facility for chewable tablets.

Market data indicates a significant compound annual growth rate (CAGR) for the global chewable tablet market, projected to reach substantial values in the coming years. For instance, recent reports suggest a CAGR of over 7% for the global nutraceutical chewable market from 2022 to 2030, driven largely by North America and Europe, with Asia-Pacific showing the fastest growth. This highlights the immense potential for brands to capitalize on this expanding market segment by partnering with expert providers of Chewable Tablet OEM&ODM Service.

Comprehensive Manufacturing Process: Crafting Excellence in Chewable Tablets

The manufacturing of high-quality chewable tablets through an OEM/ODM model is a meticulously controlled process, spanning from conceptualization to final packaging. Unlike traditional industrial components that might involve casting or forging, chewable tablets rely on precision blending, granulation, and compression techniques. The overall process is governed by strict quality protocols, ensuring product safety, efficacy, and consistency.

Key Stages in Chewable Tablet OEM/ODM Service:

- 1. Formulation Development & Material Sourcing: This initial phase involves conceptualizing the product based on client specifications (e.g., active ingredients, target audience, desired benefits). Expert formulators select appropriate active pharmaceutical ingredients (APIs) or nutraceutical compounds along with excipients – inactive ingredients that facilitate processing and enhance the product's attributes. Common excipients include binders (e.g., microcrystalline cellulose, povidone), disintegrants (not primary for chewables, but important for dissolution), lubricants (e.g., magnesium stearate), glidants (e.g., colloidal silicon dioxide), diluents/fillers (e.g., lactose, dextrose, mannitol, sorbitol), and crucial for chewables, sweeteners (e.g., sucralose, xylitol) and flavorants. Material sourcing adheres to stringent quality standards, often requiring Certificates of Analysis (CoA) for purity and potency from validated suppliers.

- 2. Blending & Granulation: Raw materials are precisely weighed and blended to achieve homogeneity. For chewable tablets, effective taste masking and uniform distribution of active ingredients are paramount. Granulation, either wet granulation (using a liquid binder) or dry granulation (compaction/slugging followed by milling), is often employed to improve powder flow, compressibility, and prevent segregation of ingredients, which is critical for consistent tablet weight and content uniformity.

- 3. Compression: The granulated blend is then fed into high-speed tablet presses. Specialized tooling determines the tablet's shape (e.g., round, oval, animal-shaped), size, and embossed markings. Parameters such as compression force and dwell time are carefully controlled to achieve the desired tablet hardness and friability, ensuring the tablet withstands handling and shipping while being easy to chew.

- 4. Coating (Optional but beneficial): While many chewable tablets are uncoated, some may undergo a thin film coating for further taste masking, improved mouthfeel, or aesthetic purposes. This is distinct from enteric coatings, which are designed for delayed release in the intestines.

- 5. Quality Control & Testing: Throughout the entire process, rigorous quality control checks are performed. This includes in-process testing (e.g., blend uniformity, tablet weight, hardness, thickness, friability) and finished product testing (e.g., assay for active ingredient potency, microbial limits, heavy metals, dissolution/disintegration – specifically for chewables, this relates to chewability and dissolution in the mouth). Detection standards adhere to international guidelines such as ISO (e.g., ISO 9001 for quality management), GMP (Good Manufacturing Practices, often aligning with FDA standards for dietary supplements/pharmaceuticals), and client-specific parameters.

- 6. Packaging: Finished tablets are packaged into various formats, including bottles, blisters, or sachets, often in climate-controlled environments to maintain stability. Packaging design also plays a crucial role in shelf appeal and product protection.

- 7. Stability Testing & Shelf-Life Determination: Post-production, samples undergo accelerated and real-time stability testing to determine the product's shelf-life, ensuring that the active ingredients remain potent and safe throughout the stated service life (typically 2-3 years).

The Chewable Tablet OEM&ODM Service applies to a wide array of industries, including nutraceuticals, pharmaceuticals (especially pediatric and geriatric formulations), and even specialized veterinary products. A key advantage in typical application scenarios is the enhanced patient/consumer compliance due to the ease of administration and pleasant taste, which directly translates to better health outcomes and market acceptance. For example, in a pediatric setting, a flavored chewable vitamin significantly increases the likelihood of consistent intake compared to a large, difficult-to-swallow pill.

Technical Parameters and Quality Specifications

Producing high-quality chewable tablets requires adherence to precise technical parameters and rigorous quality specifications. These parameters ensure that each tablet meets predefined standards for physical attributes, active ingredient content, and overall performance. A reliable Chewable Tablet OEM&ODM Service provider will meticulously monitor and control these specifications throughout the manufacturing process.

Key Technical Parameters for Chewable Tablets:

- Hardness (Crushing Strength): Measures the force required to break a tablet. Essential for handling, packaging, and preventing breakage during transit. Typical range: 50-150 N (Newtons).

- Friability: Measures the tablet's tendency to chip, crack, or powder when subjected to mechanical stress. Expressed as percentage weight loss. Acceptable limit: typically

- Weight Variation: Ensures uniform active ingredient content per tablet. Measured by randomly selecting tablets and calculating the average weight and standard deviation. USP (United States Pharmacopeia) limits apply based on tablet weight.

- Thickness & Diameter: Controlled for uniform packaging and consistent appearance. Measured with a calibrated caliper.

- Assay (Potency): Confirms the amount of active ingredient present in each tablet, ensuring it meets the declared label claim. Typically measured by HPLC (High-Performance Liquid Chromatography) or other validated analytical methods.

- Disintegration Time (for chewables, often relates to chewability/dissolution in mouth): While not strictly disintegration in the traditional sense, this parameter assesses how quickly the tablet breaks down or dissolves in the mouth, crucial for patient experience.

- Moisture Content: Important for stability and preventing microbial growth. Controlled through drying processes.

- Microbial Limits: Ensures the product is free from harmful microorganisms. Compliance with pharmacopoeial limits (e.g., USP, EP) is mandatory.

- Sensory Attributes: Flavor, mouthfeel, and aftertaste are critical for chewable tablets. Evaluated through sensory panels.

Figure 2: Quality control procedures ensuring product integrity.

Illustrative Chewable Tablet Specification Table:

| Parameter | Typical Specification Range | Test Method | Significance |

|---|---|---|---|

| Appearance | Smooth, uniform color, no chips/cracks, distinct logo (if any) | Visual Inspection | Consumer acceptance, brand image |

| Average Weight | ±5% of target weight | USP Weight Variation | Ensures dosage uniformity |

| Hardness | 50-100 N (Nutraceuticals), 80-150 N (Pharma) | Tablet Hardness Tester | Prevents breakage, ensures chewability |

| Friability | < 1.0% weight loss | USP Friability Test | Resistance to abrasion during handling |

| Assay (Potency) | 90.0% - 110.0% of label claim | HPLC, UV-Vis Spectrophotometry | Guarantees active ingredient efficacy |

| Moisture Content | Typically < 2.0% | Karl Fischer Titration, Loss on Drying | Product stability and shelf-life |

| Microbial Limits | Conforms to USP (TAMC, TYMC, specified organisms absent) | Microbiological Assay | Ensures product safety |

| Sensory (Flavor/Mouthfeel) | Pleasant, consistent with profile, no unpleasant aftertaste | Sensory Panel Evaluation | Consumer acceptance and compliance |

These specifications are crucial for establishing product consistency, ensuring regulatory compliance, and building consumer trust. A reputable Chewable Tablet OEM&ODM Service provider will have robust testing protocols and state-of-the-art analytical laboratories to meet and exceed these standards.

Diverse Application Scenarios and Strategic Benefits

Chewable tablets offer unparalleled versatility, making them suitable for a myriad of applications across various sectors. Their ease of administration and palatability overcome common challenges associated with traditional solid dosage forms, thereby enhancing patient/consumer compliance and overall product effectiveness. The strategic benefits of employing a Chewable Tablet OEM&ODM Service extend beyond mere convenience, impacting product efficacy, market reach, and brand loyalty.

Key Application Scenarios:

- Pediatric Health: Children often struggle with swallowing pills. Chewable vitamins, minerals, and over-the-counter medications provide an appealing and safe alternative, ensuring consistent nutrient intake and medication adherence. Flavored and fun-shaped chewables further enhance acceptance.

- Geriatric Care: Elderly individuals may experience dysphagia or have difficulty swallowing due to age-related conditions. Chewable supplements and medications offer a comfortable and effective delivery method for essential nutrients and chronic disease management.

- Nutraceuticals & Dietary Supplements: The burgeoning market for vitamins, minerals, probiotics, and specialized health supplements heavily leverages chewable formats. This includes daily multivitamins, calcium supplements, Vitamin D, Vitamin C, iron, and digestive enzymes. The ease of consumption makes them ideal for daily regimens.

- Sports Nutrition: Athletes and fitness enthusiasts often require rapid nutrient delivery. Chewable protein bites, amino acids, or energy supplements provide quick absorption and are convenient for on-the-go consumption without the need for water.

- Over-the-Counter (OTC) Medications: Antacids, allergy medications, and pain relievers are frequently available in chewable forms due to their fast-acting nature and ease of use in various settings.

- Veterinary Products: Pet owners seek easy ways to administer supplements or medications to their animals. Chewable pet vitamins, joint support, or anti-parasitic treatments offer a convenient and palatable solution, improving compliance in pets.

Strategic Benefits of Chewable Tablets:

- Enhanced Patient/Consumer Compliance: The most significant benefit. Palatable flavors and easy administration directly lead to higher adherence rates, crucial for chronic conditions or consistent supplement intake.

- Convenience & Portability: No water is required for consumption, making them ideal for individuals on the go, travelers, or those in situations where water is not readily available.

- Improved Bioavailability (in some cases): For certain active ingredients, pre-dissolution in the mouth can lead to faster absorption through the oral mucosa or a more dispersed and readily absorbable form once swallowed, potentially enhancing bioavailability compared to conventional tablets.

- Taste Masking: Essential for unpalatable APIs or ingredients like certain vitamins or botanicals. Advanced formulation techniques effectively mask bitter or metallic tastes.

- Differentiation & Market Appeal: Offering a chewable format can set a brand apart in a crowded market, appealing to a broader consumer base and fostering brand loyalty through a superior user experience.

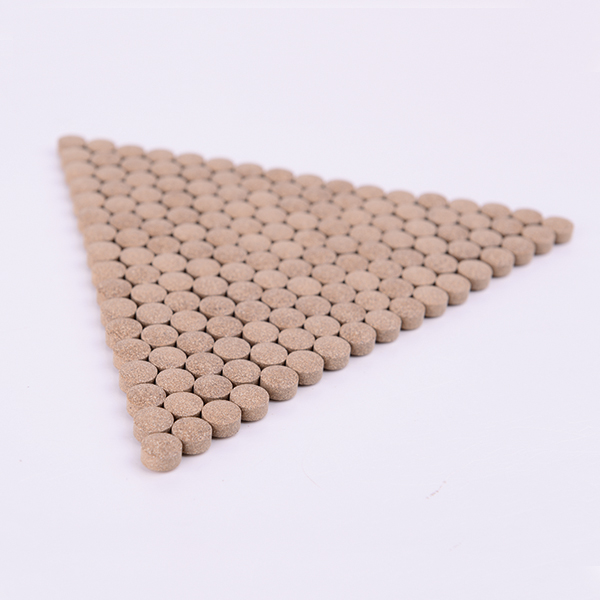

Figure 3: Variety of chewable tablet shapes and sizes for diverse market needs.

By understanding these application scenarios and strategic benefits, businesses can partner effectively with a Chewable Tablet OEM&ODM Service provider to develop innovative products that resonate with consumer needs and drive market success. The ability to cater to specific demographics and address common consumption barriers provides a significant competitive edge.

Technological Advantages and Expert R&D in OEM/ODM

A leading Chewable Tablet OEM&ODM Service provider distinguishes itself through its significant technological advantages and a robust R&D infrastructure. These capabilities are crucial for overcoming formulation challenges, optimizing manufacturing processes, and ensuring product innovation and quality. The integration of advanced science and engineering principles allows for the creation of superior products that meet diverse market demands and stringent regulatory requirements.

Key Technological Advantages:

- Advanced Formulation Expertise: This involves specialized knowledge in excipient compatibility, taste masking technologies (e.g., microencapsulation, spray drying, ion exchange resins), and texture modification (e.g., achieving optimal hardness for chewing, non-gritty texture). Expertise in stabilizing sensitive active ingredients (like probiotics or certain vitamins) within a chewable matrix is paramount.

- State-of-the-Art Manufacturing Equipment: High-speed tablet presses with precision tooling allow for consistent tablet weight, hardness, and shape, even for complex designs. Automated blending and granulation systems ensure homogeneity and efficiency. Advanced packaging lines further enhance productivity and product integrity.

- Comprehensive Quality Control Infrastructure: This includes in-house analytical laboratories equipped with cutting-edge instruments (HPLC, GC-MS, FTIR, dissolution testers, hardness testers, friabilators) to perform detailed chemical, physical, and microbiological analyses. This ensures compliance with cGMP, USP, EP, and client-specific quality standards.

- Scalability and Flexibility: The ability to scale production from small pilot batches for R&D to large commercial volumes efficiently, without compromising quality. This flexibility is vital for brands with varying market demands or those planning phased product launches.

Role of Expert R&D:

- Innovation and Customization: R&D teams constantly explore new ingredients, delivery systems, and formulation techniques to develop unique chewable products. This includes creating novel flavor profiles, integrating multiple active ingredients (combination products), and designing custom tablet shapes or sizes that enhance brand identity.

- Problem Solving and Optimization: Addressing challenges such as ingredient stability, hygroscopicity, poor flow properties, or unpleasant taste. R&D works to optimize formulations for desired physical characteristics (e.g., ideal hardness for chewing without crumbling) and manufacturing efficiency.

- Regulatory Compliance and Dossier Support: R&D teams stay abreast of evolving global regulations (e.g., FDA, EFSA, Health Canada) to ensure all formulations and processes meet the necessary standards. They can also assist with documentation and technical dossiers required for product registration.

- Stability Studies: Conducting rigorous accelerated and real-time stability studies to determine accurate shelf-life and recommended storage conditions, ensuring product potency and safety over its intended service life.

By partnering with an OEM/ODM provider boasting these technological and R&D strengths, companies can confidently launch innovative and compliant chewable tablet products, gaining a significant competitive edge in the fast-paced health and wellness market. The commitment to continuous improvement and scientific excellence forms the backbone of a successful Chewable Tablet OEM&ODM Service.

Choosing Your Ideal Chewable Tablet OEM/ODM Partner: A Comprehensive Guide

Selecting the right Chewable Tablet OEM&ODM Service provider is a critical strategic decision that can significantly impact your product's success, market entry speed, and long-term brand reputation. It's not merely about finding a manufacturer, but about identifying a true partner who understands your vision and possesses the capabilities to bring it to fruition with the highest standards of quality and efficiency. A thorough evaluation process based on key criteria is essential.

Key Criteria for Partner Selection:

- 1. Regulatory Compliance & Certifications:

- Ensure the manufacturer operates under strict cGMP (current Good Manufacturing Practices) guidelines, which are fundamental for quality assurance.

- Look for ISO certifications (e.g., ISO 9001 for quality management, ISO 22000 for food safety), HACCP, and specific market approvals (e.g., FDA registration for products sold in the US, Health Canada, TGA for Australia).

- Confirm if they can handle specific dietary certifications like Organic, Non-GMO, Vegan, Gluten-Free, Kosher, or Halal.

- 2. Formulation & R&D Capabilities:

- Assess their ability to develop novel formulations, optimize existing ones, and solve complex taste-masking or stability challenges.

- Inquire about their R&D team's expertise, track record of successful product launches, and access to proprietary technologies.

- 3. Manufacturing Capacity & Scalability:

- Evaluate their production capacity to meet your current and future demands, from small pilot runs to large-scale commercial batches.

- Understand their lead times for development, production, and delivery.

- 4. Quality Assurance & Control (QA/QC):

- Beyond certifications, ask for details on their in-process and finished product testing protocols, equipment, and personnel expertise.

- Understand their batch traceability systems and recall procedures.

- 5. Supply Chain Management:

- How do they source raw materials? Do they have a robust supplier qualification program?

- What is their approach to ingredient traceability and ethical sourcing?

- 6. Communication & Project Management:

- A dedicated project manager and clear communication channels are vital for a smooth process.

- Look for a partner who is transparent, responsive, and collaborative.

- 7. Experience & Track Record:

- How many years have they been providing Chewable Tablet OEM&ODM Service?

- Can they provide references or case studies of similar projects? A long service tenure (e.g., 10+ years) often signifies stability and expertise.

- 8. Cost-Effectiveness & Value:

- While cost is a factor, prioritize value. The cheapest option might compromise quality or lead to hidden costs later.

- Understand their pricing structure, including development fees, per-unit costs, and minimum order quantities (MOQs).

Partner Attributes Comparison:

| Attribute | Ideal OEM/ODM Partner | Less Ideal OEM/ODM Provider |

|---|---|---|

| Regulatory Adherence | cGMP, ISO, FDA Registered, HACCP certified. Proactive in regulatory updates. | Minimum compliance, reactive to new regulations, limited certifications. |

| R&D & Innovation | Dedicated R&D team, custom formulation, problem-solving, patent-pending technologies. | Standard formulations only, limited customization, no innovative solutions. |

| Quality Control | In-house analytical lab, rigorous IPQC & FQC, full traceability, stability studies. | Outsourced testing, basic checks, limited data, no long-term stability. |

| Communication | Proactive, transparent, dedicated project manager, prompt responses. | Slow, reactive, generic responses, lack of clear updates. |

| Scalability | Flexible MOQs, capacity for significant growth, efficient scale-up process. | Rigid MOQs, limited capacity, challenges with scaling production. |

| Client Support | Post-launch support, regulatory guidance, marketing insights, long-term partnership focus. | Transaction-focused, limited support after delivery, no value-add services. |

By meticulously evaluating potential partners against these benchmarks, businesses can secure a Chewable Tablet OEM&ODM Service provider that not only manufactures their products but also acts as a strategic asset, contributing to their brand's long-term success and growth in a competitive market.

Tailored Customization Solutions and Illustrative Case Studies

One of the most compelling advantages of utilizing a professional Chewable Tablet OEM&ODM Service is the unparalleled level of customization available. This goes beyond mere private labeling, encompassing comprehensive design and formulation options that allow brands to create truly unique products that resonate with their specific target audience and market niche. The flexibility in customization, combined with the proven expertise of the OEM/ODM partner, enables innovative solutions and successful market penetration.

Customization Solutions Offered:

- 1. Formulation Design:

- Ingredient Selection: From single-active ingredients to complex blends of vitamins, minerals, botanicals, probiotics, or specialized compounds. Expertise in sourcing high-quality, sustainable, and certified raw materials.

- Dosage Strength: Tailoring the concentration of active ingredients to meet specific health claims or target demographics (e.g., pediatric vs. adult formulations).

- Excipient Optimization: Selecting the right binders, diluents, and flow agents for optimal texture, compressibility, and stability.

- 2. Sensory Attributes Customization:

- Flavor Profiles: Development of bespoke flavors (e.g., natural fruit, mint, confectionery-inspired) and advanced taste-masking techniques for inherently unpalatable ingredients.

- Sweetener Systems: Choice of natural (e.g., stevia, monk fruit, xylitol) or artificial sweeteners based on client preference, dietary restrictions, and desired calorie content.

- Texture & Mouthfeel: Adjusting tablet composition to achieve specific chewability (soft, firm, crumbly, smooth) and avoiding grittiness or stickiness.

- 3. Physical Characteristics Design:

- Shape & Size: From standard rounds and ovals to custom shapes (e.g., animals, stars, fruit shapes) that appeal to specific consumer segments. Size optimization for ease of chewing.

- Color: Natural or artificial colorants to enhance visual appeal and align with brand aesthetics.

- Embossing/Debossing: Custom logos, brand names, or markings directly on the tablet surface.

- 4. Packaging Solutions:

- Primary Packaging: Bottles (HDPE, PET, glass), blister packs, sachets, or pouches. Consideration for child-resistant closures, moisture protection, and light sensitivity.

- Secondary Packaging & Branding: Custom labels, cartons, display boxes, and marketing inserts. Assistance with graphic design and regulatory compliant labeling.

Illustrative Case Studies (Fictional, based on common scenarios):

These examples highlight how a robust Chewable Tablet OEM&ODM Service can deliver tailored solutions for diverse client needs:

Client Challenge: A leading children's health brand wanted to launch a sugar-free immunity-boosting chewable tablet for kids aged 4-12, featuring a blend of Vitamin C, D3, Zinc, and Echinacea. The key challenge was to achieve a pleasant, kid-friendly taste and texture, mask the bitterness of certain vitamins, and ensure a fun, appealing shape without artificial colors.

OEM/ODM Solution: The service provider’s R&D team developed a proprietary flavor system combining natural berry and orange flavors, effectively masking the active ingredients. They utilized xylitol and stevia for a sugar-free profile. Advanced compression techniques allowed for a soft, easy-to-chew texture, and a custom teddy bear shape was designed. Natural colorants derived from fruit extracts were used. Extensive stability testing confirmed a 24-month shelf life. The product launched successfully, garnering positive parent feedback for taste and child compliance, contributing to a 15% market share increase in the first year.

Client Challenge: A sports nutrition company sought a rapidly absorbed chewable supplement containing BCAAs (Branched-Chain Amino Acids) and Electrolytes for athletes during intense workouts. The primary hurdles were the inherent bitterness of BCAAs, the need for quick solubility in the mouth, and robust packaging suitable for gym bags and active use.

OEM/ODM Solution: The team formulated the product using a specialized amino acid blend with an advanced flavor-masking matrix, achieving a refreshing citrus taste. They developed a unique tablet composition that rapidly dissolved upon chewing, facilitating quick absorption. The tablets were pressed into an ergonomic, easy-to-grip oval shape and packed in durable, moisture-resistant blister packs. Rigorous testing ensured product stability under varying temperature conditions, vital for sports environments. This product became a bestseller, praised by athletes for its convenience and rapid effect.

Client Challenge: A wellness brand specializing in plant-based products aimed to introduce a vegan, gluten-free chewable digestive enzyme tablet. The challenge lay in sourcing appropriate vegan excipients, maintaining enzyme activity during processing, and ensuring a pleasant, non-gritty texture suitable for daily consumption.

OEM/ODM Solution: The OEM/ODM partner's R&D team meticulously selected plant-derived excipients and vegan-certified enzyme sources. They optimized the granulation and compression process to preserve enzyme potency. A natural papaya flavor was developed to complement the digestive theme, and the texture was engineered to be smooth and pleasant, eliminating any grittiness. The product was certified vegan and gluten-free, quickly becoming a staple for consumers seeking plant-based digestive support, reinforcing the brand's commitment to clean label products.

These case studies illustrate the comprehensive support and tailored solutions that a reputable Chewable Tablet OEM&ODM Service provider brings to the table, translating complex ideas into successful market realities.

Trustworthiness, Quality Assurance, and Client Support

Building and maintaining trust is paramount in the B2B sector, particularly when outsourcing critical manufacturing processes. A highly trustworthy Chewable Tablet OEM&ODM Service provider distinguishes itself through unwavering commitment to quality, transparent operations, robust client support, and clear commitments regarding delivery and warranty. These elements collectively assure clients of a reliable partnership and superior product outcomes.

Quality Assurance and Certifications:

- cGMP Compliance: Adherence to current Good Manufacturing Practices (cGMP) as mandated by regulatory bodies like the FDA. This ensures that products are consistently produced and controlled according to quality standards appropriate to their intended use and as required by product specifications.

- ISO Certified Facilities: Operating within ISO-certified management systems (e.g., ISO 9001 for Quality Management, ISO 22000 for Food Safety Management Systems) demonstrates a systematic approach to quality and continuous improvement.

- Rigorous Testing Protocols: Every batch undergoes comprehensive testing for identity, purity, strength, and composition, including microbiological testing, heavy metals screening, and stability analysis. All raw materials are also rigorously tested upon receipt.

- Traceability Systems: Full traceability from raw material sourcing through every stage of manufacturing to the final packaged product, ensuring accountability and facilitating rapid response in case of any quality concern.

Delivery Cycle and Efficiency:

- Transparent Project Timelines: A detailed project timeline is established at the outset, covering formulation, raw material procurement, manufacturing, QC, and packaging.

- Typical Delivery Cycles: While subject to complexity and ingredient availability, a standard Chewable Tablet OEM&ODM Service project typically follows these approximate timelines:

- Formulation Development: 4-8 weeks

- Raw Material Sourcing: 2-6 weeks (can overlap with development)

- Manufacturing & QC: 6-12 weeks (depending on batch size and complexity)

- Total Lead Time (from concept to delivery): Approximately 12-26 weeks, subject to project specifics and client responsiveness. Rush options may be available for critical needs.

- Efficient Supply Chain Management: Proactive inventory management and strong relationships with validated suppliers minimize delays and ensure consistent raw material availability.

Warranty and Customer Support:

- Product Warranty: A clear warranty commitment on product quality, guaranteeing that products meet agreed-upon specifications and are free from manufacturing defects. This is typically backed by comprehensive liability insurance.

- Dedicated Account Management: Clients are assigned a dedicated project manager who serves as a single point of contact, ensuring seamless communication and effective issue resolution throughout the project lifecycle.

- Post-Delivery Support: Continued support for any post-launch queries, including assistance with regulatory updates, reorders, or further product iterations.

- Confidentiality Agreements: Strict adherence to non-disclosure agreements (NDAs) to protect client formulations, intellectual property, and business strategies.

Frequently Asked Questions (FAQ):

A1: MOQs vary based on the complexity of the formulation, specific ingredients, and packaging. Typically, MOQs for chewable tablets range from 50,000 to 200,000 tablets per batch, but specific project discussions can clarify exact figures tailored to your needs.

A2: Yes, a reputable Chewable Tablet OEM&ODM Service provider has in-house regulatory experts who can guide you through the compliance requirements for various international markets (e.g., FDA, EFSA, Health Canada) and assist with necessary documentation for product registration and claims.

A3: Advanced taste-masking technologies such as microencapsulation, spray drying, specific excipient blends, and sophisticated flavor systems are employed. Our R&D team conducts sensory evaluations to ensure the final product has an appealing taste profile.

A4: Comprehensive QC testing includes physical parameters (hardness, friability, weight variation, thickness, diameter), chemical assays for active ingredient potency, microbiological tests, heavy metals analysis, and stability studies to confirm shelf-life. All testing is performed in cGMP-compliant laboratories.

A5: Many OEM/ODM providers are increasingly offering sustainable packaging solutions, including recyclable materials, post-consumer recycled (PCR) content, and reduced plastic options. Discuss your specific environmental goals with your chosen partner.

The commitment to trustworthiness, rigorous quality assurance, efficient delivery, and comprehensive customer support makes a Chewable Tablet OEM&ODM Service provider an invaluable partner in bringing high-quality, market-ready products to consumers worldwide.

Conclusion: Your Strategic Partner in Chewable Tablet Innovation

In a market that increasingly values convenience, efficacy, and consumer experience, chewable tablets stand out as a highly desirable dosage form. For brands aiming to expand their product portfolios or enter new segments, partnering with a specialized Chewable Tablet OEM&ODM Service provider is not just a practical choice; it's a strategic imperative. Such a partnership transcends mere manufacturing, offering a comprehensive ecosystem of expertise, innovation, and quality assurance that drives significant competitive advantages.

The journey from initial concept to a market-ready chewable tablet is intricate, demanding profound knowledge in formulation science, stringent adherence to cGMP and other regulatory standards, and sophisticated manufacturing capabilities. A top-tier OEM/ODM partner brings this entire spectrum of services, including advanced R&D for novel formulations, precision manufacturing, rigorous quality control, and robust supply chain management. This allows your business to focus on its core competencies – marketing, sales, and brand development – while relying on a trusted expert for product realization.

By leveraging an established Chewable Tablet OEM&ODM Service, companies can capitalize on growing market trends, cater to diverse consumer needs (from pediatric to geriatric), and introduce differentiated products that stand out in a crowded marketplace. The ability to customize ingredients, flavors, shapes, and packaging ensures that the final product not only meets functional requirements but also aligns perfectly with brand identity and consumer preferences. Furthermore, the inherent trustworthiness built through transparent processes, guaranteed quality, and dedicated client support ensures a long-term, fruitful collaboration. Choosing the right OEM/ODM partner is an investment in quality, efficiency, and sustained market success, positioning your brand at the forefront of innovation in the health and wellness industry.

References

- United States Pharmacopeia and National Formulary (USP-NF). General Chapters: Physical Tests.

- European Pharmacopoeia (Ph. Eur.). Monographs for Dosage Forms.

- International Organization for Standardization (ISO) 9001:2015 - Quality management systems.

- US Food and Drug Administration (FDA) Current Good Manufacturing Practice (cGMP) Regulations for Dietary Supplements.

- Research and Markets. Chewable Tablets Market - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast.

- AAPS Journal. Formulation strategies for enhancing palatability in pediatric and geriatric drug products.

- Journal of Pharmaceutical Sciences. The importance of excipients in pharmaceutical dosage forms.

- Nutrition Business Journal (NBJ). Trends in the global nutraceutical market.

Post time:Aug - 21 - 2025